About materials

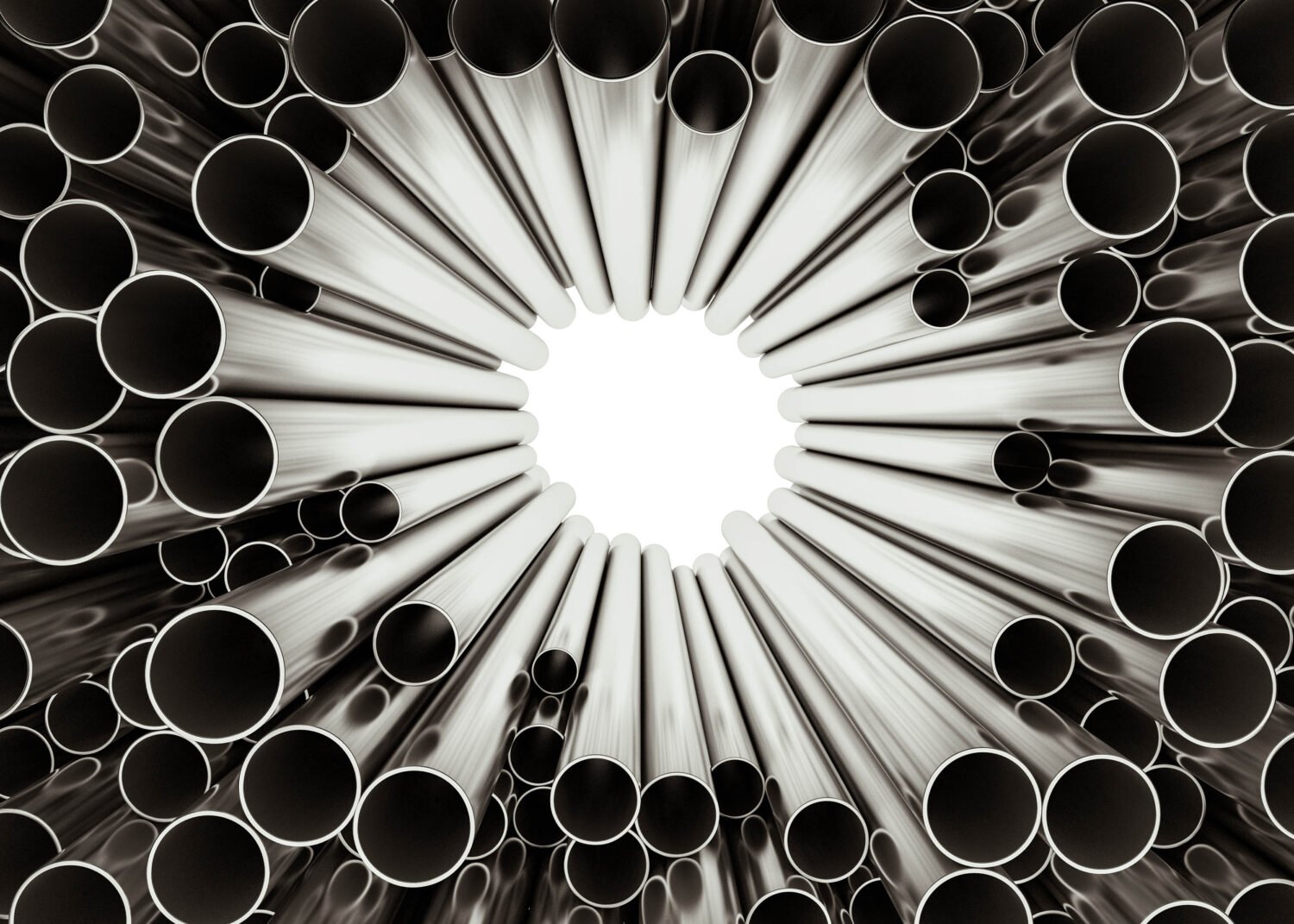

Stainless Steel

Stainless steel has become the most mainstream material for heated towel rails at present.The advantages are durability, corrosion resistance, versatile shape, and the ability to use a variety of surface treatments. The disadvantage is that the price will be a little more expensive than most materials.

Mild Steel

Mild steel is the mainstream material for radiators. It has low hardness and is easy to weld. But the shape is only rounded. Since its own corrosion resistance is low, the surface must be painted. The material and processing cost is low. If it is used as the material of electric towel rail, its service life will be lower than that of stainless steel, and once a small piece of coating comes off the surface, it will rust quickly.

Aluminum

Most of the aluminum alloys currently used to make electric towel racks are space aluminum materials. It has a lower material cost, general corrosion resistance, and the surface can be sprayed and oxidized. The disadvantage is that the material is thin, low grade, and can not be finely polished, resulting in its production of products often existing in the case of sharp edges.

Brass

The brass heated towel rail is the highest-end product available. However, due to its high material cost and production cost, only very few markets are currently selling related products.

About Shapes

The tubular heated towel rail is currently the most mainstream and popular style. It is mainly divided into two kinds of round and square tubes. There are various tube diameters, various shapes of stainless steel tube type, so stainless steel heated towel rail can have a thousand different design shapes.

Round

Square

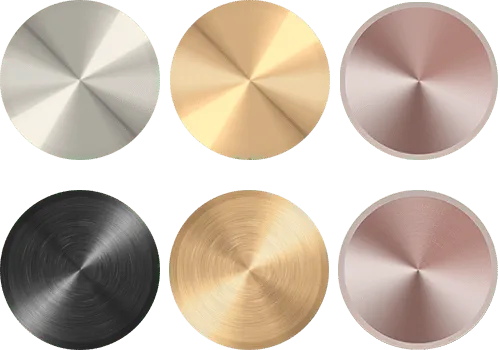

About Surface treatment

Surface Treatment | Description | Color | Display |

|---|---|---|---|

Electroplating | Electroplating is the most popular metal surface treatment that can be done in a wide range of colors. At present, the common colors in the market are chrome plating, gold, rose gold, brushed gold, brushed rose gold, and gunmetal grey. *Popular in the global market. |

|

|

Brushed Nickle | Brushed nickel is one of the effects of polishing, which is more of a subtle, softer-looking finish. It has a slightly brushed appearance with a semi-satin finish. *Popular in the USA, Australia, and New Zealand markets. |

|

|

Silver | The silver surface is the other effect of polishing. It is made through multiple polishing processes and finished with a mirror-like finish. *Popular in the global market. |

|

|

Painting | The painting process is mainly divided into two types: powder coating and painting. They can both be made glossy or matte and can be made in a variety of colors. The mainstream colors in the market at present are matte black and matte white. *Popular in Australia, New Zealand, USA, and European markets. |

|

|

Oxidation | Oxidation is a surface treatment process specifically for aluminum. It can be done in many different colors, just like electroplating, and the current mainstream colors are brushed gold, brushed rose gold, and gunmetal grey. |

|

|

Treatment | Description |

|---|---|

Electroplating

| Electroplating is the most popular metal surface treatment that can be done in a wide range of colors. At present, the common colors in the market are chrome plating, gold, rose gold, brushed gold, brushed rose gold, and gunmetal grey. *Popular in the global market. |

Brushed nickel

| Brushed nickel is one of the effects of polishing, which is more of a subtle, softer-looking finish. It has a slightly brushed appearance with a semi-satin finish. *Popular in the USA, Australia, and New Zealand markets. |

Silver

| The silver surface is the other effect of polishing. It is made through multiple polishing processes and finished with a mirror-like finish. *Popular in the global market. |

Painting

| The painting process is mainly divided into two types: powder coating and painting. They can both be made glossy or matte and can be made in a variety of colors. The mainstream colors in the market at present are matte black and matte white. *Popular in Australia, New Zealand, USA, and European markets. |

Oxidation

| Oxidation is a surface treatment process specifically for aluminum. It can be done in many different colors, just like electroplating, and the current mainstream colors are brushed gold, brushed rose gold, and gunmetal grey. |

Surface treatment that can be done on various materials

FEATURES | Electric Plating | Brush Nickle | Mirror | Painting | Oxidation |

|---|---|---|---|---|---|

Stainless Steel |

|

|

|

|

|

Mild Steel |

|

|

|

|

|

Aluminum |

|

|

|

|

|

Brass |

|

|

|

|

|